MAHLE issues latest advice on defective starter motors

Date: Tuesday 09 April 2024

“The incorrect use of starter motors can lead to thermal overload of the solenoid, leading to failure of the starter motor,” explains Alan Povey, quality, qarranty and technical manager at MAHLE.

As many technicians will be aware, internal combustion engines cannot generate torque from standstill and a starter motor is therefore required to start the engine.

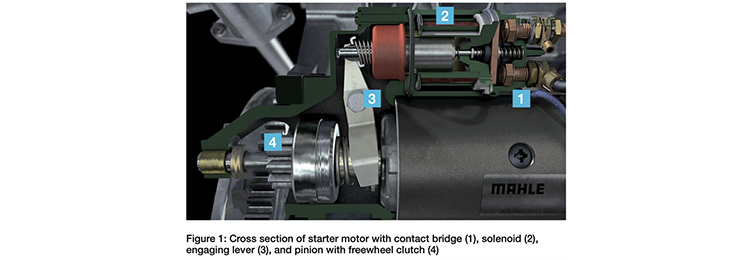

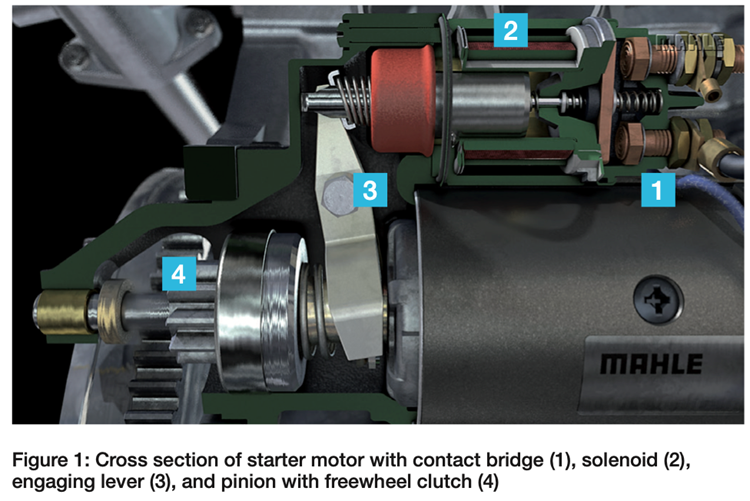

Starter motors may vary in size, design, and performance depending on the application, but they are all based on the same operating principle: pressing the start button or turning the ignition key causes current to flow to the starter motor solenoid.

This activates the engaging lever to push the starter pinion into the ring gear of the engine flywheel. At the same time, a contact bridge closes the electrical circuit to the starter motor – the starter motor turns which starts the engine.

Once the engine is running, the starter motor is no longer needed. The circuit is interrupted, and the solenoid withdraws the pinion from the ring gear and returns it to its original position.

The starting process places the engine under enormous load, explains Povey.

He added: “This is generally not a problem, as a start cycle usually lasts only a few seconds. However, if the starter motor is operated repeatedly in quick succession over an extended period without sufficient breaks, the windings of the solenoid act like a heating coil.”

Repeated instances of high-power consumption can cause the solenoid to heat up so much that the winding burns out.

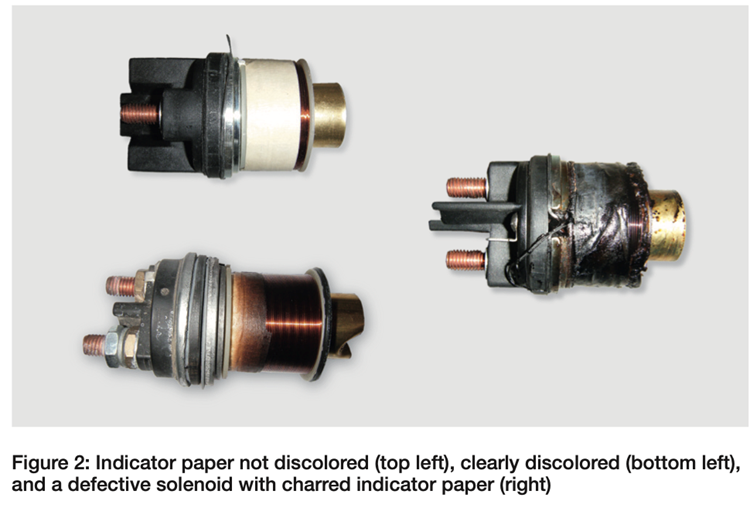

Such overloads can be seen on the indicator paper that is wound around the solenoid during manufacture and becomes discoloured when a certain temperature is exceeded.

Marked discoloration of the indicator paper is thus clear evidence of thermal overloading of the starter motor.

The starter motor should never be operated continuously for more than 30 seconds and should then be allowed to cool down for at least two minutes, advises Povey.

The starting process may be initiated no more than three times in a row, otherwise a longer break will be needed. MAHLE strongly advises against improper use of the starter motor (for instance to bleed the fuel injection system after changing the fuel filter).

Fig 1

Fig 2

Technicians can read more information in the latest technical bulletin from MAHLE here or watch this explanation video here